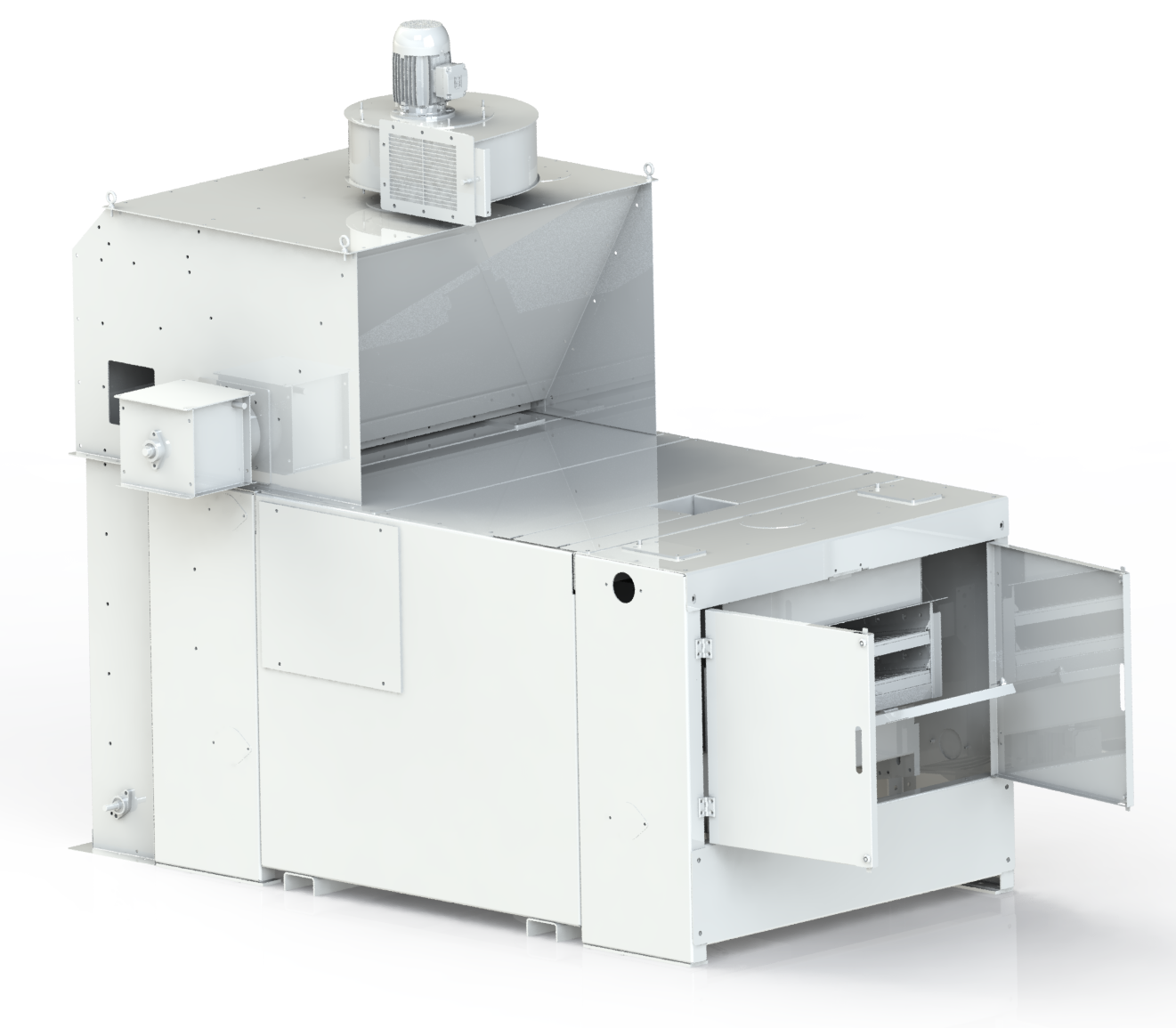

NS AGRI 50 Separator-cleaner

APPLICATION

The cleaner separator NS AGRI 50 is designed for multiple uses and meet all cleaning needs : from basic cleaning upon reception and before storing to very fine cleaning before shipment.

It has a 50 T/H rate based on wheat, for basic cleaning but will also be adapted to all type of cleaning and all type of grains and seeds : corn, oat, soya, rapeseed, sunflower, seeds …

OPERATION

Schneider Jaquet cleaners operate on the basis of planetary movement, recognized as allowing better distribution of grains all over the sifting surface and thus enhancing the flow rate and yield.

This type of crumbler-sifter-screener-scrubber best reconciles the most reliable methods currently available on the market for this task.

This equipment is made of a suspended box operating on the basis of planetary movement by eccentric masses, driven by a vertical shaft and a low-power consumption engine.

1-The grain enters and is distributed in slick on the complete width of the machine.

2–It has two lumps breaker screens, which, by crossing of the good product, hold the big waste or the superior grades to conduct them to big waste exits.

| Model | Flow rate (T/H) | Surface area of screens (m2) | Dimensions* (mm) | Weight(kg) | Power(kW) | ||

| Length | Width | Height | |||||

| NS AGRI 50 | 50 | 4 |

2 670 |

1 895,50 |

2 046 |

1 580 |

0,75 |

* V111 Version

3-The good product falls on two crumbling screens that allow the separation of the small waste (crumbling) to conduct them to the crumbling exit.

4-The product is conducted in slick to the aspiration at the output that allows the extraction and the efficient, total and immediate recycling of the light waste: shells, hollow grains, light grains, cracks, by the crossing of air that passes counterflow through a cascade of grains.

De-gumming balls used to unclog the screens Highly adaptive machine with a wide range of options