Bulk: a market with strong growth potential

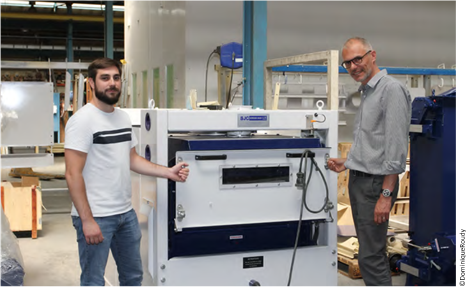

In October 2017, a new adventure began for Mehdi Benbouali and Philippe Guyomard, respectively chairman and senior partner of a French manufacturer of sorting, calibrating and sifting solutions. In three complementary areas, the two leaders want to retain the company’s top-end expertise and reputation to diversify into the bulk market and develop exports.

“There is great potential in the bulk market, and more than ever we want the company to play a role in the sector”, says Mehdi Benbouali, aged 47, an EDHEC graduate in charge of management and finance at the Anjou-based enterprise.

Operating in Saint-Barthélemy-d’Anjou, in the suburb of Angers, Schneider Jaquet is celebrating its 150th anniversary this year. A real “made in France” success story, our contact tells us: “Since 1868, the company has undergone several phases. In 1956, the Cesbron group, experts in silo equipment, took over Schneider Jaquet, which operated in Alsace. Then, after developing separator cleaners at the beginning of the 1980s, the company passed into the hands of the enterprise Jean-Stolz, a well-known business in the animal nutrition sector. After Jean Stolz passed away in 2007, Patrick Hardy took over the business. Ten years later, with Philippe Guyomard (58 years old), my partner, a National Advanced School of Engineering graduate experienced in automotive equipment, in charge of production here, we became aware of the chance to take over Schneider Jaquet and we decided to embark on this adventure.”

It’s not only about separator cleaners:

The partnership now works extremely well, as evidenced when interacting with staff. Although machines used to clean cereals “are a niche market” as Mehdi Benbouali admits, the company has a catalogue large enough to meet the needs of a wide range of customers in the cereal storage sector, specifically silo operators, ‘Cumas’ (agricultural equipment user cooperatives), farmers, installers and aggregators.

Our flagship SJC Schneider Jaquet equipment, the separator cleaners, performs impressively, are compact and are highly valued for their easy maintenance; they come in several models and are customisable. They are combined with general-purpose sifters which perfectly meet the needs of sifting or separating specific products. The scrubbers, used at the beginning of the cycle in the pre-cleaning stage, are also worthy of mention, because they are ideal for products with high impurity levels. Due to their static device which uses gravity, connected to a suction tool, the scrubber also removes light waste such as grain flow dust.

The barley calibrator is designed to separate grains of different sizes using several screens that are operated with planetary movement. In addition to this material, which is becoming increasingly popular, densimetric tables should not be forgotten. These are specially designed for seed stations and mills, completing a reliable, robust range of machines.

This machine catalogue is added to the large volume de-mixer (100 t/h) with three sifting levels: the SNS Bio 100. The latter has been full-scale tested in a silo with 70% wheat and 30% faba beans with a de-mixing success rate of close to 100%.

Schneider Jaquet wants to move up a gear in bulk and exports

Drawing on its knowledge, expertise and consequent presence in the cereal sector with over 2,000 machines commissioned since 2000 and an annual production of around 120 machines, including 95 cleaners, the Anjou-based enterprise wants to move up a gear in the French bulk market and focus on exports.

“I think,” Mehdi Benbouali notes, “that we must acquire a greater presence in the bulk industry. Therefore, we’d like to attend more trade shows and ramp up our presence among the sector players.” With over 20 employees at the Saint-Barthélemy-d’Anjou site, including 16 production workers (welders, painters, boilermakers and fitters), 2 engineering consultants, as well as the sales and marketing team, turnover (EUR 4.5 million for the last 2 years, with exports accounting for 20%) is stable with a slight increase in exports: “We operate in Canada, and Eastern Europe as well as North and West Africa, two continents where we would like to strengthen and scale up our image. We have major projects to export and I’m not going to deny that we’re eyeing South America and Asia too,” the Schneider Jaquet chairman added.

Innovation is essential.

The numerous windows of opportunity include innovation, a priority for Schneider Jaquet according to Mehdi Benbouali: “We’ve mastered the production machines, but must now improve productivity, technical know-how and control in-company processes. We must work on innovation to meet our customers’ requirements. Ongoing projects notably include machine energy saving, streamlining maintenance and operator safety.” Schneider Jaquet, which is working on the idea of small, human-sized machines for farmers, holds all the right cards to move into the bulk sector, a rapidly-changing industry.